Environment Policy

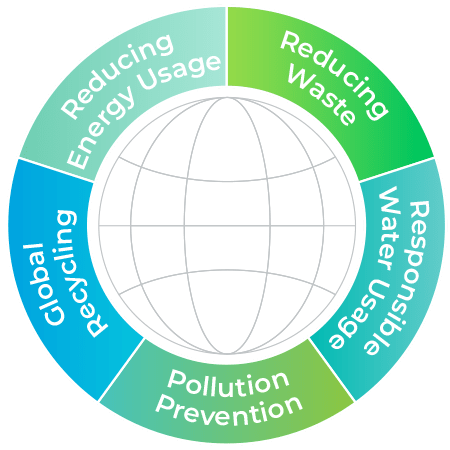

At PAXXUS, we are committed to providing you with the highest quality flexible material solutions designed and produced in an environmentally responsible manner that goes beyond industry regulations, laws, and codes of practice.

We pledge to keep exploring opportunities to prevent pollution, improve our environmental performance, and promote the use and development of sustainable materials.

We promise to remain vigilant about how our actions today impact our world tomorrow. We are excited to continue to collaborate on projects that have the power to positively affect the world we all share.